Our expertise in supply chain and logistics optimization involves using IoT sensors, RFID tags, and GPS trackers. These technologies monitor and track inventory, assets, and vehicles. AI analyzes the data to optimize routes, schedules, and deliveries, resulting in more efficient and reliable logistics operations.

Products:

1. IoT sensors:

LoRaWan based temperature and humidity sensors Magnetic installation, FDA food grade material and the ability to store data when network fails make it very suitable for cold chain industry.

2. RFID tags

Radio Frequency Identification (RFID) is the wireless non-contact use of radio frequency waves to transfer data. Tagging items with RFID tags allow users to automatically and uniquely identify and track inventory and assets. RFID takes auto-ID technology to the next level by allowing tags to be read without line of sight.

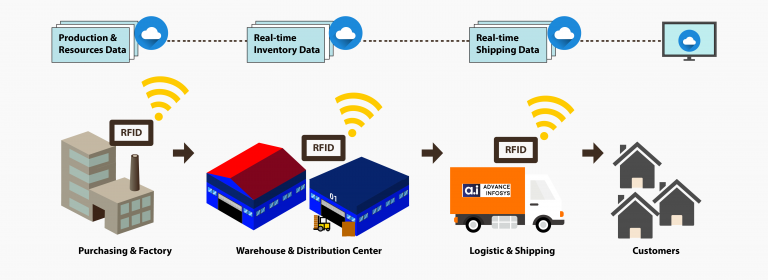

The use of RFID technology in supply chain and logistics will help a company to improve its operation efficiency across Manufacturing, Distribution and Transportation. Moreover, RFID technology that allow real-time visibility of materials and assets keep the manufacturing process with effective resources planning.

Image: RFID in the Supply Chain

3. GPS trackers

Real-time monitoring of temperature conditions

GPS tracking devices equipped with temperature sensors play an important role in real-time monitoring of temperature conditions within refrigerated containers. This capability ensures that perishable goods are maintained within specified temperature ranges throughout the entire journey, safeguarding their quality and safety.

Geofencing for Route

Geofencing technology allows logistics managers to create virtual boundaries along the route. This ensures that drivers adhere to pre-determined routes and stops, minimizing the risk of temperature excursions and ensuring that the cold chain remains intact. Geofencing also aids in optimizing routes for efficiency and timeliness.

Remote Monitoring and Alerts

Advanced GPS tracking systems provide remote monitoring capabilities, enabling logistics managers to receive real-time alerts in case of temperature fluctuations or other anomalies. Immediate notification allows for prompt intervention, helping prevent potential damage to sensitive cargo and ensuring compliance with temperature-sensitive regulations.

Data Logging and Reporting

GPS tracking devices equipped with data logging capabilities capture and store detailed information about temperature conditions, transit times, and geolocation.

Historical Data Analysis for Continuous Improvement

The accumulation of historical data over time allows logistics managers to conduct in-depth analysis. This analysis helps identify patterns, assess the performance of specific routes or carriers, and implement continuous improvement strategies. Historical data also serves as a valuable tool during audits or quality assurance processes.